New Mimaki UJF points to great future for G J Plastics.

G J Plastics’ owner Graham Croston with the company’s new Mimaki UJF-3042

G J Plastics’ owner Graham Croston with the company’s new Mimaki UJF-3042

A recent investment in state of the art direct-to-substrate Mimaki digital print hardware by UK, Greater Manchester based G J Plastics highlights the company’s commitment to equipping its design and fabrication team with the very latest and highest spec kit. The company’s 14-strong team – headed up by owner and founder Graham Croston, produce a vast array of acrylic display products, signage and promotional items in house, from initial concept through to manufacture, enabling them to deliver high quality products with rapid response times and a real attention to detail that make products unique to each customer.

A young Croston may well have been influenced by the iconic movie The Graduate, when an even younger Ben Braddock (Dustin Hoffman) was offered the sage business advice by his mentor; “I want to say one word to you ... just one word. PLASTICS! There’s a great future in Plastics, think about it.”

After honing his skills as a mechanical engineer, Croston quickly spotted the potential of the plastics industry and set up G J Plastics almost 22 years ago. Starting out by cutting and forming plastic sheet using a routing machine that he built himself from spare parts, Croston has steadily developed the expertise, capability and resource to position the business as one of the UK’s most widely respected plastic engineering facilities.

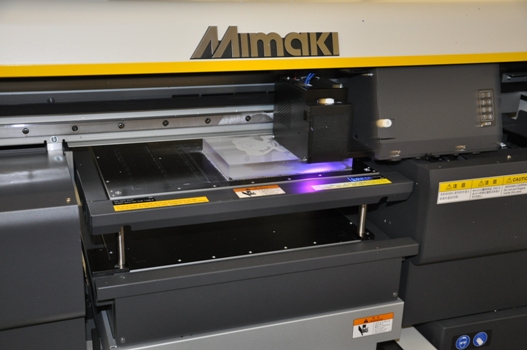

G J Plastics uses its Mimaki UJF-3042 to print direct to acrylic The company takes investment in equipment very seriously and Croston is keen to ensure that the skills of his highly qualified design and fabrication teams are supported by the best available tools. Accordingly, their latest acquisition is a Mimaki UJF-3042 A3 format flatbed UV printer, supplied by UK and Irish distributor, Hybrid Services via its authorised reseller PaperlinX and joins their existing roster of solvent and latex roll fed printers and existing large format flatbed printer together with a pair of laser cutters, two CNC routers and a cutting plotter as well as heat bending machines and vacuum formers.

G J Plastics uses its Mimaki UJF-3042 to print direct to acrylic The company takes investment in equipment very seriously and Croston is keen to ensure that the skills of his highly qualified design and fabrication teams are supported by the best available tools. Accordingly, their latest acquisition is a Mimaki UJF-3042 A3 format flatbed UV printer, supplied by UK and Irish distributor, Hybrid Services via its authorised reseller PaperlinX and joins their existing roster of solvent and latex roll fed printers and existing large format flatbed printer together with a pair of laser cutters, two CNC routers and a cutting plotter as well as heat bending machines and vacuum formers.

Croston explains the rationale behind the purchase; “We’re always looking for new ways of developing our offering to customers and expanding our range of products and services. We needed a compact flatbed printer with the capability to print at very high resolution on a range of different substrates and objects. Having undertaken a fair bit of research and discussing our needs with Darren Walker at PaperlinX, the Mimaki stood out as a real contender. A demo at Hybrid’s showroom in Crewe rendered the purchase a no-brainer and the deal was done.”

GJ Plastics specialises in bespoke commissions, one-off prototypes and short runs; “the sort of thing that many of our competitors just don’t seem to be interested in,” as Croston puts it. “The quality of our output and the attention to detail is what sets G J apart,” he explains, “and the new Mimaki provides us with a quality of print onto all manner of media and physical items that is simply breath-taking.”

“A recent job involving a highly detailed photographic print of a supercar onto an acrylic block actually delivered a sharper, more vibrant image when printed direct to the acrylic on the UJF-3042 than the output from a high quality photographic printer. The added attraction of the Mimaki being able to print both primer, as well as varnish coats makes the capabilities of this machine quite remarkable,” he concludes.

PaperlinX’s Darren Walker adds, “It’s always a pleasure working with Graham and his team at G J. They are very open-minded and always receptive to new ideas which enhance their standing in a rather specialised sector of the industry. The idea of investing in the optional ‘Kebab’ accessory for the UJF-3042 was put forward, enabling direct printing to cylindrical objects. The team at GJ were fascinated and are already printing direct to glass vases and acrylic tubes for promotional purposes. I think Graham is on a mission to identify as many new and innovative uses for this machine as he possibly can!”

For Graham and his team at GJ there clearly is a great future in plastics!

http://www.gjplastics.co.uk/

You can Tweet, Like us on Facebook, Share, Google+, Pinit, print and email from the top of this article.

![printMAX promises podium prices this summer printMAX podium-promo[1]](/modules/mod_raxo_allmode/tools/tb.php?src=/images/stories/machines/printmax-podium-promo1.jpg&w=250&h=200&zc=1)