Company to unveil high speed variable-pagination digital booklet printing solution at drupa.

Domino K630i_Monochrome printing press

Domino K630i_Monochrome printing press

UK based Domino, a developer and manufacturer of coding and printing technologies, has confirmed that it will showcase its K630i high speed compact single-engine duplex ink jet press at drupa 2016 (Messe Düsseldorf, 31 May – 10 June, Stand No A23 in Hall 5). The company, which is an autonomous division of Brother Industries Limited, will use the exhibition to demonstrate the machine producing multi-page booklets on an integrated system in partnership with Kern AG and IBIS Bindery Systems, at speeds of up to 7,000 booklets per hour.

Bryan Palphreyman, Domino Product Manager said,

“We have been talking with IBIS and Kern for some time, and I am delighted to be finally working with both teams at drupa to deliver this flexible solution which not only facilitates high production output and is geared for rapid job change, but also minimises manning requirements and material waste.”

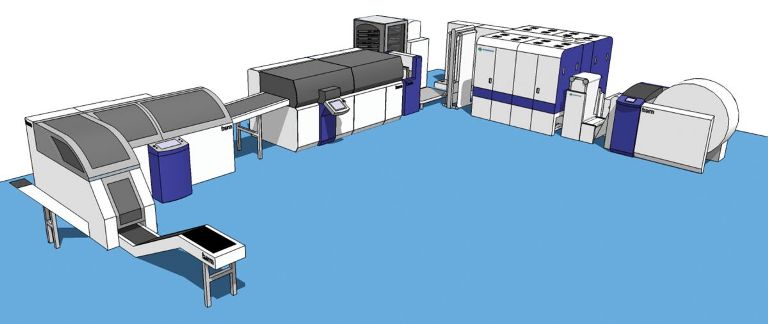

As part of this integrated system, Kern, a supplier of mailroom solutions, will use its Kern 100 unwinder to deliver web media to the K630i where the relevant booklet content is printed. The Kern 130 rotary cutter will then take the printed web and supply individual cut sheets to an in-line IBIS Smart-binder which, depending upon the booklet type, folds and either wire stitches or glues the sheets together, and if required, can add a pre-printed cover.  Domino+Kern+IBIS Booklet Production Line

Domino+Kern+IBIS Booklet Production Line

At the exhibition, Domino will demonstrate the complete flexibility of the system by producing a range of different A4 booklet types varying continually between a 100 page glued technical manual, through to 20 page stitched or glued exam papers, and a 40 page stitched puzzle booklet with printed cover, without stopping or wasting sheets. Domino intends to show that this flexible solution will highlight the real production efficiency of the combined system.

The ‘24/7’ rated production process can deliver the web at speeds of up to 150m/min and produce finished booklets of up to 200 pages (50 sheets), changing content and booklet page-count on the fly and producing up to 7,000 booklets per hour.

Of special interest to attendees will be the fact that each individual sheet has a 2D code printed within the unprinted margin area, which is scanned through the production process at the Smart-binder ensuring 100 per cent reliability in each finished booklet. A three-knife trimmer finishes the booklet to perfect size, delivering a completed booklet available for immediate despatch.

Palphreyman concluded,

“We believe the market wants complete solutions, rather than just products, and this integrated production line demonstrates this to our customers. We see the book market as a high growth opportunity for Domino and we are using drupa to demonstrate our intent to enter into this sector.”

For further information on Domino, please visit www.domino-printing.com

You can Tweet, Like us on Facebook, Share, Google+, Pinit, print and email from the top of this article.

Copyright © 2016, DPNLIVE – All Rights Reserved.