Domino N610i digital ink jet label press was the machine of choice for Charapaks diversification.

Charapak, Alfreton, DerbyshireIn an effort to supply both existing and new customers with high quality, digitally printed, one of the UKs market leaders in the design and manufacture of specialist corrugated packaging, Charapak, has recently diversified into the labelling sector following an investment in Domino’s N610i digital ink jet label press.

Charapak, Alfreton, DerbyshireIn an effort to supply both existing and new customers with high quality, digitally printed, one of the UKs market leaders in the design and manufacture of specialist corrugated packaging, Charapak, has recently diversified into the labelling sector following an investment in Domino’s N610i digital ink jet label press.

Since 1980 when the Company started, it now employs 127 people with an annual turnover of £13 million from its plant in Alfreton, Derbyshire. Since a management buyout in 2008, the company has achieved growth and taken off to where they are today.

From their website, Charapak lists their services as “design and manufacture of corrugated packaging, promotional displays and retail ready packaging. Our sister company Charapak Integrated Fulfilment can provide a comprehensive outsourcing service for storage, packing and fulfilment, while Siliconpak produces a range of papers and materials for use in the food industry.”

They have now added Charapak Labels to their group and related services offered. They have extended their range from their core business utilising their award-winning flexo post print and litho-laminating processes to producing specialist corrugated packaging, promotional displays and retail ready packaging to integrated fulfilment and specialist coated packaging.

Domino N610iThe company serves both domestic and international customers in the industrial, food and drink, automotive, retail and e-commerce market sectors.

Domino N610iThe company serves both domestic and international customers in the industrial, food and drink, automotive, retail and e-commerce market sectors.

In 2015, they were awarded the prestigious ‘Company of the Year’ award in the Derby Telegraph Business Awards. This was an award they were delighted to win against over 200 other entries.

Like all companies, they are looking at ways of expanding their range of services. This came about when a long-standing customer enquired about the possibility of Charapak supplying digitally printed labels. Being quick to spot an opportunity, Richard Smith, Owner and Managing Director of Charapak said

“This was our chance to broaden our service offering beyond corrugated packaging and capitalise on the vast potential of the digital labels market. We set out to find the right digital print supplier that we could partner with.”

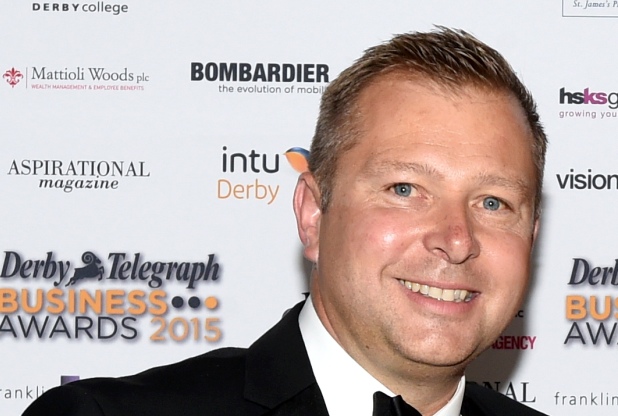

Richard Smith, Managing Director of CharapakHe continues: “Charapak operates to three core business principles: quality, innovation and flexibility. We look for these attributes in any supply partner we work with. After an intensive review of the different print technologies available during which print quality, productivity, colour vibrancy, durability and cost of ownership were all assessed, followed by a further evaluation of the shortlisted suppliers in terms of their commercial stability, accessibility and the level of service support they could provide, we decided that Domino was the company that could deliver on all fronts.”

They set about researching suitable machinery and came across Domino. They were offered the opportunity to visit and conduct a series of trials at Domino’s headquarters in Cambridge. This led them to conclude that the N610i digital ink jet label press was able to address three key requirements for them. Ease of operation was crucial, as Charapak was venturing into a new market and so required a system that was easy to operate and understand. Being a production machine, it exceeded their requirements in terms of speed and the capability to print long-lasting, durable labels for their customers.

Michaela Smith, Business Manager, Charapak LabelsCharapak Labels Business Manager, Michaela Smith, comments:

Michaela Smith, Business Manager, Charapak LabelsCharapak Labels Business Manager, Michaela Smith, comments:

“Our customer was previously having their labels flexo printed and were carrying huge amounts of stock on the shelf and were spending a lot of money on inventory, storage and obsolescence. We realised that the way forward was for short run, digitally printed labels that would lift their print from mediocre to outstanding, and that’s exactly what we’ve done! We decided on the six colour N610i because it was extremely important for us and our customer that the colours were vibrant and that they ‘jumped off the print’. We have found that the quality of the labels printed on the Domino is outstanding compared to what we previously had.”

Michaela continues: “The key benefits in using the Domino press are its productivity, the quality, and the durability of the labels that are absolutely first class. Our customer now has zero inventory, lack of obsolescence and we print to order – they are very happy!”

Richard concludes with

“It’s been a great learning curve for us, but already we’re really happy with our decision to partner with Domino. The support and service we have received has been second to none and we would have no hesitation in recommending Domino to anyone who asks us, or have any hesitation in making the same decision again. With the continued support from Domino, we’re expecting impressive business growth.” He is delighted that the digital press has helped Charapak transform its business by exploring new business.