This Week In Business

Print’s not dead. How Hearst is using social to power-up its papers.

Analizo launches Europe's first algorithm-as-a-service, bringing robo-investing capabilities to the wealth management industry

Applegreen wins prestigious European SME Award

Mimaki Tx300P-1800 already proving a Fashionable Choice

Irish Stock Market

Applegreen wins prestigious European SME Award

Star of 2016 award won by Applegreen Applegreen, the #1 motorway service area operator in…Irish Stock Exchange Quarterly Statistics Q3 2016

Q3 2016 statistics show over 35,000 securities listed on Irish Stock Exchange markets…ISE shows growth

Irish Stock Exchange listing figures grow to over 35,000 securities Quarterly statistics…Irish Stock exchange extends to 28 companies

Dalata Hotel Group joins the ISE’s Main Securities Market Dalata Hotel Group (Dalata),…#IPOready companies graduate from ISE leadership programme

High-potential companies have graduated from #IPOready #IPOready is the Irish Stock…Quarterly Statistics - Irish Stock Exchange

Q1 2016 statistics show 34,382 securities listed on ISE markets. Main headlines: Listings…ISE The Place To Be!

Irish Stock Exchange wins No.1 slot in Great Place to Work Awards. Would you like a great…Venn Life Sciences Joins The ESM

Adding a euro quotation for investors. Venn Life Sciences, the growing Contract Research…

World Economy

Print’s not dead. How Hearst is using social to power-up its papers.

The Newspaper business is dead? Don’t tell that to Hearst. By Brett Lofgren | September…Press Release From ISE

ISE and NASDAQ OMX announce intention to bring Dual ISE/US Market Access to Irish…Sappi First-Quarter Profit Falls

Company says result is due to paper and pulp price decline. Sappi Ltd., the world’s…How global manufacturing is changing.

Ireland is changing and the savvy business has to be aware of changing global trends.3D…High Consumption Foodstuffs in DRC:

High Consumption Foodstuffs in DRC: Where Are the Surpluses and Deficits? By Dr…Xerox wins print contract for UK Government

Xerox to deliver cost efficiencies in print services to UK public sector The UK Cabinet…Disposable income drops

New figures just released show that household disposable income in Ireland fell by 0.4…Ireland’s richest 300 worth €62bn

The 300 richest people in Ireland are now worth more than €62bn. The figure is staggering…

Business & Finance

Applegreen wins prestigious European SME Award

Irish Stock Exchange Quarterly Statistics Q3 2016

ISE shows growth

Irish Stock exchange extends to 28 companies

#IPOready companies graduate from ISE leadership programme

Quarterly Statistics - Irish Stock Exchange

World Stock Market

Hans‐Ole Jochumsen re‐elected as FESE President

Euro rates fixed – but for how long?

GLOBAL STOCKS and COMMODITIES

Snapshot of Irish shares and European stocks over Christmas

Markets surge on Central Banks' intervention

U.S. Stocks Update Wednesday 23rd November 2011

Economy, Tenders & Invenstment

Prior information notice of tender.

Tender Opportunity Here at DPNlive, we are always looking for business opportunities for…Print tenders

Want to do the printing for the Houses of the Oireachtas? Below is a table of three…

- Details

- Written by David Tiernan

- Parent Category: Cottage Industry

- Category: Artisan Ireland

by David Tiernan

In 1987 we won supplier of the Year Award from Drogheda and Dundalk Dairies, an independent dairy involved in liquid milk for bottling and door to door sales – an indicator of a very high quality milk production. We did consider cheese making then but our twin sons were just babies so we decided to focus all our time and energy on them.

In January 2004 it became apparent that milk prices were falling. It was becoming more difficult to make a living from the dairy and our future looked bleak. We had by this time introduced the Montbeliarde cow from the Jura region in France – a dual purpose cow with excellent quality milk, replacing the Holstein Fresian. In France their milk is used exclusively in the making of Comte, Gruyere and other mountain cheeses.

My wife Margaret and I visited the region in France to see if it were possible to make a similar cheese here in Ireland. We were very well received and after a lot of discussion we ordered what equipment would be needed.

On our return home we set about converting an old stone building in where the twins’ great-grandmother would have made her butter! She was a dairy instructress many years ago. A chance encounter at a farm we visited in France brought us our cheese maker, Julien Rouillaud, who helped us make the first cheese in July 2004. I must admit to being hooked on the actual process of turning our milk into huge 40 kg wheels of cheese.

On our return home we set about converting an old stone building in where the twins’ great-grandmother would have made her butter! She was a dairy instructress many years ago. A chance encounter at a farm we visited in France brought us our cheese maker, Julien Rouillaud, who helped us make the first cheese in July 2004. I must admit to being hooked on the actual process of turning our milk into huge 40 kg wheels of cheese.

In our first year we made a small amount, less than 1000kg as we were not sure how it would turn out. Julien however proved himself to be an exceptionally competent and skillful cheese maker. At only 24 years of age he had an unbelievable knowledge of his craft. Without him I do not believe our cheese would have been as good as it is.

As we only make Glebe Brethan in the summer months when the cows are eating grass it was possible for Julien to return the following year and get production started again. This time I paid particular attention to everything he was doing and continued cheese making when he returned to his home. The first week was extremely stressful – lots of telephone calls to Julien were the norm every week. As time went on I became more confident and began to enjoy the process. Julian is still in regular contact with us.

It really is a wonderful feeling each morning walking the cows up to be milked and knowing that by midday we will have two more wheels of beautiful cheese in our cellar. And you never know who is going to be eating it! In the past few years our cheese has been presented to both Prince Charles while he was in Belfast and to the Queen, on her visit to Dublin.

It really is a wonderful feeling each morning walking the cows up to be milked and knowing that by midday we will have two more wheels of beautiful cheese in our cellar. And you never know who is going to be eating it! In the past few years our cheese has been presented to both Prince Charles while he was in Belfast and to the Queen, on her visit to Dublin.

As the years have moved on we have changed over from direct sales of our cheese at Farmers Markets. They were both time consuming and exhausting. We now supply a few distributors – Sheridan’s and Traditional Cheese Company. We still supply a number of shops and restaurants ourselves which is good to get feedback from the public and the chefs.

We are increasing production every year, but only at a pace that feels comfortable. Also the export market is important to us, with cheese going to the UK and Holland on a regular basis. A few weeks ago we took part in a Bord Bia promotion in Selfridges in London along with a lot of other small high quality Irish food producers. Thanks to the magnificent work of the Bord Bia London staff we are now listed as one of their cheese suppliers. This is a wonderful opportunity for a small business like ours. Thanks to them and Sheridan’s cheesemongers we now have the chance to grow our export market.

As Margaret and I are the third generation of Tiernans to work this farm we are very proud of our cheese. I am sure my grandmother gets a kick out of it too! For now it seems as though our sons will pursue separate careers so we will keep going ourselves for another few years anyway.

Please see website for list of awards won.

Tiernan Family Farm

Glebe House, Dunleer, Co.Louth.

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it." mce_' + path + '\'' + prefix + ':' + addy56698 + '\'>'+addy_text56698+'<\/a>'; //-->

Twitter: glebe brethan

- Details

- Written by Graham Roberts

- Parent Category: Cottage Industry

- Category: Artisan Ireland

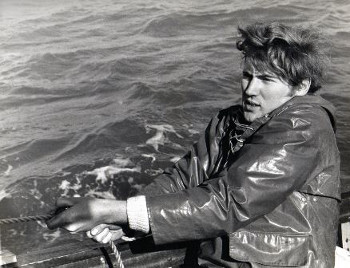

My name is Graham Roberts and I live and work in a small fishing village, Aillebrack near Ballyconneely set in beautiful Connemara, County Galway, Ireland.

Trá Heel Beach, Aillebrack, Ballyconneely © by Paul Stickley

I live with my wife Saoirse and four children in our home overlooking the Atlantic and a beautiful sandy beach just across the road. We have a windswept garden with a small vegetable patch where we try to teach the children where food comes from.

Connemara Smokehouse - Graham, Saoirse Roberts & Family

I run the Connemara Smokehouse and I often leave around 4 or 5 o’clock in the morning to take a two minute drive, 5 minute cycle or 10 minute walk to the Smokehouse which is perched on the edge of the Atlantic beside my parents home and at the top of Bunowen Pier.

Connemara Smokehouse © by Saoirse Roberts

My mother and father started the business in 1979 and my father was a fisherman before that. This means that there is a huge wealth of knowledge, experience and respect behind what we do. I have grown up with the business and learned from my father the methods, and the techniques of traditional curing and smoking. It gives me great pleasure to now see my children following in the same footsteps and learning from me in the same way I did with my father.

A young fisherman John Roberts © by Paul Stickley

John & Bridget Roberts founder of Connemara Smokehouse © Connemara Smokehouse

The most important thing for us has always been quality and all of our products are traditionally hand prepared to ensure the very best results.

THE PROCESS

Filleting:

The first step to filleting salmon is to have a very sharp knife. This is achieved by skilfully hand sharpening the blade. The most common size salmon for smoking is 3-4kg in weight. A fish this size is about 3 to 4 years old and produces two pieces of smoked salmon about 800g - 1100g. The salmon are hand-filleted and the 30 pin bones are removed. The fillets are then washed to remove all loose bones and scales and are placed in the cold room for about one hour in order for the water to drain off before salting.

© by Saoirse Roberts

Salting:

The fish are traditionally dry salted by sprinkling a dry sea salt onto the fillets. The salt is left on the fish for about 8-10 hours, depending on the size of the fish. The salt draws out the moisture and prevents the growth of bacteria. The salt is then washed off using fresh water.

© by Saoirse Roberts

Smoking:

Beech wood is used to give our fish its beautiful flavour. The smoke is fanned through the fish for about 8-10 hours (depending on their size) and this is followed by a further 8-10 hours of drying time. The smoking stage is so important and we monitor this with great care. The age and simplicity of the kiln, as well as weather conditions can have a great effect on the smoking of the fish. Our smoking process is not automated. The timing of the smoking is determined solely on the basis of our expertise. After the fish have been smoked they are put into a different cold room for 24 hours before slicing. At this stage the oil in the fish can re-congeal before slicing.

© by Saoirse Roberts

Slicing:

Our fish is sliced by hand and also by machine, depending on quantities or our requirements. As with the filleting, it is very important to have an extremely sharp knife for slicing the smoked salmon.

Once a skilled slicer like Graham has finished there is no difference between hand and machine sliced other than that the machine needs to be cleaned!

© by Saoirse Roberts

It is very important to pay close attention to detail and my work is a big part of what defines me. I believe that everything you do in life should be done to the best of your ability. I have enormous passion for what I do and take great pride when I see the enjoyment people get from my products. Some people think I’m crazy because of the long hours I work, but some of them spend three hours in their car every day commuting to jobs they don’t enjoy, so I figure if I have a job that I really enjoy, live in a place that I love and make a living, then I’ve got it pretty good.

With everything we do at the Smokehouse, the impact on the environment is a major concern, as we must not only think of the here and now, but for future generations to follow. We use sustainably sourced wild and organically farmed fish prepared in the traditional ways of my family because they are the best. Handfilleting, dry-salting and resting the fish are essential components of traditional methods that require time and attention.

We also take various measures towards environmental sustainability such as:

- 1. We use Airtricity (wind powered electricity) for our electrical supply.

- 2. The main ingredient used for cleaning is elbow grease and water followed by a biodegradable detergent for sanitisation.

- 3. We source our fish locally, so that it is at its freshest, it does not have to be transported for hundreds or thousands of miles and it supports the local economy and local community.

- 4. Other measures such as line fishing for tuna were worked upon by my father and me to help develop an environmentally friendly way of catching tuna.

- 5. We also work very closely with the Marine Institute towards conservation of Wild Salmon stocks (and have done for over 30 years).

I am extremely involved in every aspect of my business. Experience and handed-down knowledge have taught me what works best, and this provides a continued involvement in what I do, always improving, always discovering aspects that make my products delicious and healthy.

© by Saoirse Roberts

I love spending time with family and friends, specially my wife and children. I really enjoy the simple pleasures of life like walking on the beach with the children and discovering a completely new world in their eyes. We love foraging on the shore and in the fields for a shellfish feast or maybe a lovely mushroom soup!

© by Saoirse Roberts

Cooking is really important to me and we love having friends over for dinner and experimenting with new dishes. We all sit down together as a family at dinner time and catch up on the day’s events.

© by Saoirse Roberts

I am very content between home and work, but I do like to travel and try new foods and through them enjoy different cultures.

I feel really lucky to live where I do and have a job I enjoy. I am very grateful to my four beautiful children and above all to my wife Saoirse who makes this all possible.

All of our products are available to buy at the smokehouse and also online at www.smokehouse.ie

© by Saoirse Roberts

We run tours at the smokehouse on fixed times and days and also for private groups by arrangement.

People can drop in anytime to our factory shop where we have all of our products for sale and we are always happy to explain how it all works.

© by Saoirse Roberts

Connemara

Smokehouse Ltd.

Bunowen Pier,

Aillebrack,

Ballyconneely,

Connemara,

Co. Galway

Ireland.

saoirse@smokehouse.ie

info@smokehouse.ie

Tel: +353 95 23739

Fax: +353 95 23001

www.smokehouse.ie

Copyright © 2012, DPNLIVE – All Rights Reserved

- Details

- Written by Administrator

- Parent Category: Cottage Industry

- Category: Artisan Ireland

By Ellen Neumann

13th April 2012

Ciara O’Dowd grew up in the hospitality industry. Her family owns and operates Woodlands Country House in Killinierin, Gorey, Co. Wexford, a 5-star guesthouse renowned for its scrumptious food and gracious hospitality. She worked with Glanbia Foods as a systems administrator for many years. She married Paddy O’Dowd and together they started their first production line: that would be their children: Cein age12, Aoife age 6, Darragh age 9

|

|

|

Her passion for food began at an early age and for many years she has been producing artisan products at home as gifts for guests, family and friends. Everybody got a hamper for Christmas - no surprises there! Because of the encouragement she received and the demand for home produce, she decided to develop a small artisan food business last year with just a couple of her favorite products. As you can see, she has a lot of favourites! There are now over 24 products in the range. Ciara refers to herself as an accidental entrepreneur. She lives in the Sunny South East Coast of Ireland, an area renowned for its divine fruit growing.

Her passion for food began at an early age and for many years she has been producing artisan products at home as gifts for guests, family and friends. Everybody got a hamper for Christmas - no surprises there! Because of the encouragement she received and the demand for home produce, she decided to develop a small artisan food business last year with just a couple of her favorite products. As you can see, she has a lot of favourites! There are now over 24 products in the range. Ciara refers to herself as an accidental entrepreneur. She lives in the Sunny South East Coast of Ireland, an area renowned for its divine fruit growing.

With a commercial kitchen at her disposal at Woodlands Country House, the temptation to start her own small business was impossible to resist, and “Ciara’s Pantry” producing for Ciara’s Artisan Foods Ltd was born. Ciara registered with the local health board and took the necessary environmental and food safety courses drew up a quality manual and HACCP plan (Hazard Analysis and Critical Control Point) and began developing her range of products. When she actually looked at what was on offer in the specialist food shops, she was amazed at the quantity and quality of imported foods, which many people perceived to be Irish, and indeed a lot of the produce was actually mass produced and not of the best quality at all. She developed her brand, designed her packaging, and did numerous high profile product tastings around the county to give her brand sufficient exposure.

A local business started at a Country Market would be the first to sell her products. Ciara’s business grew as two local artisan shops immediately contacted her to supply them with her products. Following feedback from their customers, more shops came on board by word of mouth. It is a business that is growing “organically”.

|  |  |

Ciara entered and won a “Dragons Den” style competition in Wexford, which raised her profile and gave her great media coverage. She now supplies shops in the South East and her business is continuing to expand in a natural manner. Ciara is currently working to expand to a larger premise that will be purpose built to increase volume and meet demand while maintaining the integrity of the product and keeping it pure and free from additives, powders, stabilizers, artificial sweeteners and over processing.

All ingredients are sourced, to ensure freshness and quality. Only natural ingredients are used, and indeed some are just freshly picked from her extensive garden, in tandem with the seasons whenever possible. Gardening is her second love and the whole family is involved in maintaining these wonderful gardens. Ciara, Paddy and their three darling children are always out and about in the family gardens although picking currants can become a little monotonous, it most certainly is the “Good Life”. Indeed she awoke one morning in September to be met by a horse outside the kitchen door - the horses had a little jail break from their paddock and had eaten whole four baskets of the previous evening apple picking much to the children’s dismay! Paddy helps with the gardening side of things as much as possible, builds and mends the fences, He is of course the chief taster of all the products; an enviable job indeed ! Ciara uses vegetables and herbs fresh from her garden whenever possible

Ciara’s Pantry produces a delicious range of all natural products made from fresh ingredients, all sourced to ensure freshness and quality. Absolutely no artificial colours, flavorings, artificial preservatives, sweeteners, additives or powders are used. Traditional methods produce the sweet and savoury jellies, which in the past were considered one of the crowning glories of the dining table because of their versatility and convenience. These are made in the old fashioned open pot, in small batches, and dripped through muslin overnight, to maintain the quality, clarity and flavor. The jellies are made from real fruits, vegetables and pectin stock from apples to give a wonderful smooth consistency, unlike most commercial jellies which are made from powdered pectin’s and flavouring. Many may remember their grannies turning stools upside down and tying muslin to make crab apple jelly! …well it’s still pretty much the same today. You most likely would not find Char-grilled pepper Jelly, Jalapeno or even balsamic jelly was ever on Grannies’ old school menu!

Ciara’s Pantry offers a sensational range of savoury and sweet jellies. The savouries enhance cheeses, meats, the sky is the limit! The sweet jellies are bursting with zingy fresh fruity flavour.

A new and exciting selection of dressings is made from only the best natural ingredients and pro-biotic cider vinegar which is full of health benefits. Enjoy flavour combinations that will make every day a salad day for the whole family. Dipping sauces may also be mixed through with mayonnaise or cream cheese for variations. These are all totally natural in beautiful vibrant colours, Cheeky Chilli & Ginger, Basil & Lime with Pine Nuts, Raspberry Salad Dressing to name but a few.

A range of chutney’s will delight you and warm up any evening with a classic balance of sharp and sweet, together with the warmth of spices that will remind you of open log fires, Christmas, days gone by and will leave your taste buds tingling all year round. These chutneys are made from the freshest ingredients as well, harvested from the garden at the peak of perfection. Some chutney is made with wines and port. Only the highest quality ingredients are used. One even takes two days to make but the result is pure class in the world of chutney, which makes it stand apart from the rest.

A range of chutney’s will delight you and warm up any evening with a classic balance of sharp and sweet, together with the warmth of spices that will remind you of open log fires, Christmas, days gone by and will leave your taste buds tingling all year round. These chutneys are made from the freshest ingredients as well, harvested from the garden at the peak of perfection. Some chutney is made with wines and port. Only the highest quality ingredients are used. One even takes two days to make but the result is pure class in the world of chutney, which makes it stand apart from the rest.

Fruit vinegars made with cider vinegar rely solely on the preservative qualities of the sugar and vinegar to maintain the quality of Fruits. This allows the finished product to taste simply and sublimely of fruit.

Of course Ciara’s Pantry offers traditional preserves such as Raspberry & Apple, Blackcurrant & Apple or Four Fruit marmalade to grace your table everyday. Delicious combinations of Fruit to give an intensely flavoured spreadable jam! For the more adventurous, there is Raspberry with White Chocolate and Kahlua which is simply delicious with chocolate torte. A beautiful range of smooth, delicate curds made from Free Range Eggs are currently in development. Lemon Curd, Coffee Curd and Lime Curd will be available in stores soon and each has fabulous recipes which will be available on Ciara’s Pantry website (www.ciaraspantry.com)

The possibilities are endless but the entire mission of her company is as follows: “everything must taste as if it was made in your own kitchen by a master chef!” Believe me, they do! Ciara hopes to grow and diversify in the coming year and expand into new markets. She also hopes to develop an online sales business. Her range is new and exciting. While they are a niche product, they are just incredible to taste and enjoy; a true gastronomic delight. All Products are made in small batches for the true connoisseur, every mouthful a testament to the work and love that has gone into each handmade jarful.

The possibilities are endless but the entire mission of her company is as follows: “everything must taste as if it was made in your own kitchen by a master chef!” Believe me, they do! Ciara hopes to grow and diversify in the coming year and expand into new markets. She also hopes to develop an online sales business. Her range is new and exciting. While they are a niche product, they are just incredible to taste and enjoy; a true gastronomic delight. All Products are made in small batches for the true connoisseur, every mouthful a testament to the work and love that has gone into each handmade jarful.

Ciara’s passion for food is truly reflected in each jar.

At Ciara's Pantry they fervently believe that using natural ingredients sourced locally produce mouth-watering tastes to compete with the best food-producing regions of the world. Ciara’s Pantry is located at Killinierin, Gorey, Co Wexford, Ireland.

Using local ingredients produced with nature's best intentions helps to boost Ireland’s agri-food industry and protect local jobs. If you'd like to help put Ireland on the gourmet map by stocking Ciara’s products, all contact details are on the website.

*A special thanks to Anne Devereaux

Email info@ciaraspantry.com

Twitter https://twitter.com/#!/search/realtime/ciaraspantry

Facebook http://www.facebook.com/ciaraspantry?sk=photos

Copyright © 2012, DPNLIVE – All Rights Reserved

- Details

- Written by Margaret O’Farrell

- Parent Category: Cottage Industry

- Category: Artisan Ireland

Written by Margaret O’Farrell

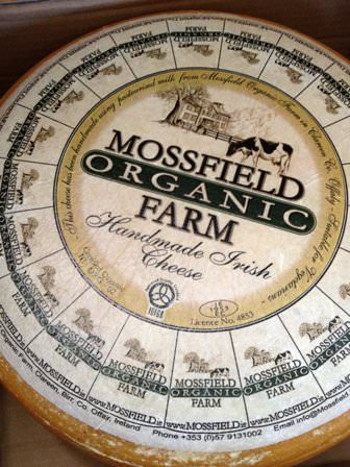

Mossfield Organic Farm is owned and operated by Ralph and Lorraine Haslam and is based in the Midlands of Ireland in Clareen, Birr, Co Offaly at the base of the Slieve Bloom Mountains. Did you know that the Slieve Bloom Mountains are reputed to be the oldest mountain range in the world? Even older than Mount Everest! Ralph wonders does that make him the oldest farmer in the world. He says it feels like he is sometimes!

Mossfield Organic Farm is owned and operated by Ralph and Lorraine Haslam and is based in the Midlands of Ireland in Clareen, Birr, Co Offaly at the base of the Slieve Bloom Mountains. Did you know that the Slieve Bloom Mountains are reputed to be the oldest mountain range in the world? Even older than Mount Everest! Ralph wonders does that make him the oldest farmer in the world. He says it feels like he is sometimes!

There is so much history attached to the old house and farm! The family of Charles Carroll, a signatory on the US Declaration of Independence lived on the property. Charles’ ancestor, Daniel, a descendant of the O’Carroll’s - Lords of Ely - left the property around 1659 and travelled to Maryland, USA. I am sure when Daniel was leaving he did not realise that it would be a grand descendant of his that would be one of the 56 signatories on the American Declaration of Independence.

After the departure of the Carroll’s, the next famous family to live on the land was the Stoney family. Bindon Blood Stoney was a brilliant inventor who devised an ingenious way to build dock walls (and also designed the first diving bell). He was born in Clareen. Bindon and his brother, George (who ‘invented’ the electron) worked at one point as astronomical assistants on the great Leviathian telescope at Birr Castle

The land at Mossfield consists of limestone pasture with a grass interwoven with wild herbs and clover - producing lush green grass - so suitable for dairy farming. Ralph and Lorraine have been farming here since 1970.

In 1999 the Haslam’s made the decision to “go organic”; a brave decision at the time. However, being forward thinking is an important factor in today’s Ireland. Farming is after all a business, and there is a need to constantly rethink and reinvent methods and procedures. !

In 1999 the Haslam’s made the decision to “go organic”; a brave decision at the time. However, being forward thinking is an important factor in today’s Ireland. Farming is after all a business, and there is a need to constantly rethink and reinvent methods and procedures. !

Like so many farmers Ralph had to start thinking ‘outside the box’ as sticking with just traditional farming was no longer a viable proposition for the farm. In 2005 it seemed a natural progression.... Mossfield was producing delicious organic milk, so why not look at producing cheese?

In the initial stages the cheese was made off-site, but as its reputation grew and it won many awards, it was time to re-evaluate again The decision was made to build a purpose-built cheese manufacturing facility on the farm. This was a huge decision! Ralph and Lorraine so believe in their cheese that they knew it was the right thing to do.

The cheese is now hand-made at the facility using milk straight from the farm. Lorraine supervises the cheese making, it is all handmade, and hand turned. This Gouda style cheese is available in a number of different flavours and as they use vegetarian rennet it is suitable for vegetarians.

The younger cheeses have a lovely mild flavour, and as it matures the taste gets stronger. My personal favourite is the cumin seed cheese! Absolutely delicious!

Ralph is a passionate advocate of the Mossfield organic brand and has a successful track record in selling. Despite limited resources the brand has achieved a high profile, and has consistently won awards - Great Taste, Bridgestone Award, and Irish Food Writers Guild Award.

The popularity of the range of cheeses has grown enormously from those early days. Now Mossfield Organic cheese is in demand not just in Ireland, but has become an international brand. It is now available in various European countries, and most recently in the USA.

The popularity of the range of cheeses has grown enormously from those early days. Now Mossfield Organic cheese is in demand not just in Ireland, but has become an international brand. It is now available in various European countries, and most recently in the USA.

On his last trip to Ireland, it is rumoured that Bruce Springsteen bought the entire stock of Mossfield Cheese from one Dublin shop - he liked it so much!

Ralph and Lorraine are not resting on their laurels though!

Jonathon, Ralph and Lorraine’s son, has now joined the team. Jonathon runs The Organic Store in nearby Birr, but recently has been working with his father on developing other by-products from their milk!

Cartons of Mossfield Organic Milk are now in selected stores. The newly branded Cheddar - Slieve Bloom Cheddar is available as well as the Mossfield Organic Buttermilk and yoghurt. Mossfield Organic Butter will soon be hitting the shelves as well. Just wait until you taste their cream cheese! I’ve had a preview tasting - it is delicious.

Mossfield Organic will continue to diversify and review its product range, building upon the consumer’s desire for pure, clean and delicious products.

Ralph Haslam

Mossfield House

Clareen

Birr

Co. Offaly

Tel: 00353 (0) 86 8928375

Web site: www.mossfield.ie

Facebook: www.facebook.ie/MossfieldCheese

Copyright © 2012, DPNLIVE – All Rights Reserved

- Details

- Written by Alfie McCaffrey and Margaret O'Farrell

- Parent Category: Cottage Industry

- Category: Artisan Ireland

by Alfie McCaffrey and Margaret O'Farrell

Clarence

There was a slop bucket kept by the kitchen door for any food waste. If there was any wastage from the fields that was fed to the pigs as well! There was no real cost to keeping the pig and in the end you had bacon and ham for Christmas.

I remember visiting my Granny’s house on the edge of Roscrea town. Many of the neighbours kept pigs in their suburban gardens and all the neighbours saved their household slops to feed the pigs and got a nice piece of bacon in return. This was “true community farming”.

Why did this tradition stop?

Why did this tradition stop?

It stopped because it was perceived as being a “poor” thing to do. If you kept pigs and cured your own bacon you obviously could not afford to buy it. Such a concept seems so strange to us today, when we all love the idea of rearing our own meat. As Ireland got wealthier many people moved away from the rural farming areas to a more urbanized lifestyle in the cities. The pork and bacon industry turned into a much more concentrated process.

What goes into the animals feed is enough to terrify any normal soul.

What goes into the animals feed is enough to terrify any normal soul.

Pigs don’t do ‘sick’, they are either healthy or dead. To minimize loss of animals, the pigs in most farms are feed a diet that includes antibiotics – just in case they should get some illness! Where do all these antibiotics end up? In the meat, of course! When the meat is eventually processed it is extremely tasteless, anemic looking and fat free. At that point it does not even come close to resembling real pork There are all sorts of arguments about how this type of intensive farming is not ‘bad’ for the animals. However, it’s not natural. Pigs are natural rooters and foragers. To be enclosed in slatted, concrete barns is just plain wrong. Sows are confined to farrowing pens where they cannot sit or turn around – that is not natural.

Th ere is good news for Irish pigs - well, for some pigs anyway.

ere is good news for Irish pigs - well, for some pigs anyway.

There is a tide change here in Ireland. More people are looking for pork raised in the traditional way. Free range pig breeding is on the rise. In a free range system pigs have access to the outdoors 24 hours a day, seven days a week. Pigs are very clever animals. If it is cold and miserable outside they will stay tucked up in a nice bed of straw and only venture outdoors when necessary.

Since we started keeping pigs almost 5 years ago, we have met many people who are doing the same. Not a month goes by without an enquiry to buy some piglets.

Some folks are just keeping a couple of pigs for themselves. Others like us are trying to build a business selling free range pork products. Free range farming is a very different process from the intensive, profit driven factory system.

Our pigs are born here on our farm, at Oldfarm, Redwood, Lorrha, Nenagh, Co. Tipperary. They usually venture outdoors within 48 hours of their birth. It will only be a few steps outside the sty door before they scamper back inside to the cosy warmth of straw. The mothers all give birth naturally with no interference from us other than a watchful eye. No farrowing stalls are used. In the five years we have been in business we have never lost a baby pig due to the mother lying on it. Perky & babies

It is a most amazing thing to listen to Mother Pig ‘talk’ to her babies. She makes one particular noise to let them know she is going to lie down to feed them, then another happy grunting sound as she suckles. Within a short time the piglets start to nibble on feed. We feed our pigs a mixture of gmo free barley and wheat which is supplemented with vegetables from a local market gardener as well as whey and cheese from an organic farm.

Over time every pig we’ve ever had has developed a preference for something or other. Perky is very partial to potatoes. All the pigs love cheese and apples. Clarence loved bananas. Socky loved celery, and for Pinky it was oranges! You just never can tell!

The difference between meat from pigs reared in a natural environment and those from factory farms is spectacular. Thankfully, there are a growing number of people who appreciate our efforts.

There are still challenges facing us.

Land: Extra land would be nice - but not everyone wants to lease land for pig rearing - they do a good job of clearing out weeds and roots but not everyone appreciates that, and also agricultural land is so so expensive.

Meal: costs fluctuate - depending on the crop and harvest. Also we are adamant about non-GMO [genetically modified organisms] and sourcing meal that has been grown in a completely non-gmo way is important to us, and could become more difficult!

Fuel charges - which of course adds to the delivery charge. It would be nice if there was some sort of distribution system for small producers.

Education: a lot of our time is spent on educating consumers about our product - clean meat, no gmos (which an awful lot of people still know nothing about - so therefore they don’t even consider that factor).

Labeling: there is an ongoing battle of the labels; artisan, organic, outdoor reared, free range, gmo free. The term “Artisan” is used to such an extreme that it has become difficult to define. We are aware of large companies, using factory reared pigs, and selling their products under the ‘artisan’ label. Yet we fit the true meaning of the category.

We have chosen not to go the labeled ‘organic’ route as the costs would be prohibitive. We are a small holding and can only produce so much meat. The cost of being labeled organic would price our product out of the market.

The Future:

We are working with Bord Bia (the Irish Food Board) in the hope of developing a recognised free-range label. It is a slow process with so many interested parties having to be consulted. Taking these steps will hopefully give tomorrow’s consumer a better understanding of how we rear and treat our animals.

Alfie and Pigs

Oldfarm Pork

Tel: 00353 (0) 86 8100 125

Email: margaret.oldfarm@gmail.com

Web: www.oldfarm.ie

Blog: ayearinredwood.com

Facebook: www.facebook.com/OldfarmPork

{jcomments on}

Artisan Ireland

The Sweetest Thing

The Sweetest Thing. By Tom Byrne.Scratch the surface of Irish industry and you will find…Donegal’s Liquid Gold – Pure Rapeseed Oil

Donegal’s Liquid Gold – Pure Rapeseed Oil The healthy cooking oil favoured by Celebrity…A simply rural life at Waterfall Farm

by Hannah Bolger People are keen to connect with where their food is coming from…Tastefully Yours

Artisan producers of a delightful range of handmade chutneys, preserves, and…MILEEVEN Bees--Sarah's Honey

Mileeven Fine Foods was established in 1988 by my mum, Eilis Gough from her hobby of…Glebe Brethan Farmhouse Cheese

by David Tiernan In 1987 we won supplier of the Year Award from Drogheda and Dundalk…Graham Roberts - Connemara Smokehouse

My name is Graham Roberts and I live and work in a small fishing village, Aillebrack near…CIARA’S PANTRY: It's a Family Affair

By Ellen Neumann13th April 2012 Ciara O’Dowd grew up in the hospitality industry. Her…