Company launches its new portfolio in finishing for packaging and printing.

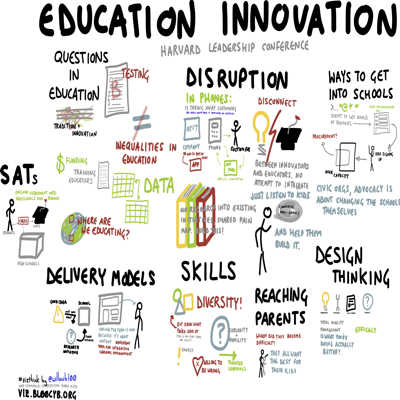

Wine stand made with 3D modelling on the Highcon Euclid, 1.4 meters (55”) HighconHighcon recently held a pre-drupa event for its customers, potential customers, analysts and press at its headquarters in Yavne, Israel. The purpose of the occasion was to demonstrate the first showing of its new portfolio of products developed for digital cutting and creasing in new markets which will be launched at drupa this year.

Wine stand made with 3D modelling on the Highcon Euclid, 1.4 meters (55”) HighconHighcon recently held a pre-drupa event for its customers, potential customers, analysts and press at its headquarters in Yavne, Israel. The purpose of the occasion was to demonstrate the first showing of its new portfolio of products developed for digital cutting and creasing in new markets which will be launched at drupa this year.

The new product range has come about as the result of the lessons learned from its customers all over the world who have been supplying the constantly growing requirements of hundreds of brands by using digital finishing capabilities for a wide range of applications.

At drupa 2016, Highcon will be showcasing digital solutions which can deliver an even wider range of applications that address the needs of packaging and printing companies.

The drupa portfolio offers a full range of digital finishing products from entry level to top-of-the-line production capability, all based on Highcon's core cutting and creasing technology. All these products will be demonstrated on Highcon's 1000m2 stand in Hall 9, C50 at the exhibition.

Highcon Beam

The Highcon Beam is designed to extend digital finishing to mainstream production. With a speed of up to 5,000 sheets per hour, this machine was developed as a robust solution to the challenges facing folding carton converters and print service providers.

Highcon Pulse

The Highcon Pulse brings digital post-print to print service providers and converters with a seamless integration into existing B2 / 29 in. sheet size workflows. Highcon's digital cutting and creasing technology enables an in-house controlled digital system that delivers improved responsiveness, design flexibility and entry into a wide range of applications in numerous markets.

Highcon Euclid III

The Highcon Euclid III is aimed at tackling today's operational challenges as well as customer’s future growth needs by opening the door to countless new opportunities in high value applications and markets, such as packaging and commercial print applications to Web-to-Pack and even 3D modelling. The 3D optional module with Highcon's Rapid Layer Manufacturing technology offers users a wide range of capabilities with disruptive speed, size and costs which Highcon maintain will unleash the power of paper. 3D models are created based on any type of substrate, including recycled board and even used offset make-ready sheets.

To learn more about this exciting new application, and the entire portfolio, listen to the webinar in the video below

You can Tweet, Like us on Facebook, Share, Google+, Pinit, print and email from the top of this article.

Copyright © 2016, DPNLIVE – All Rights Reserved.