First Finnish installation of Domino N610i takes place at Karico

Domino Karico Digital printed labels

Domino Karico Digital printed labels

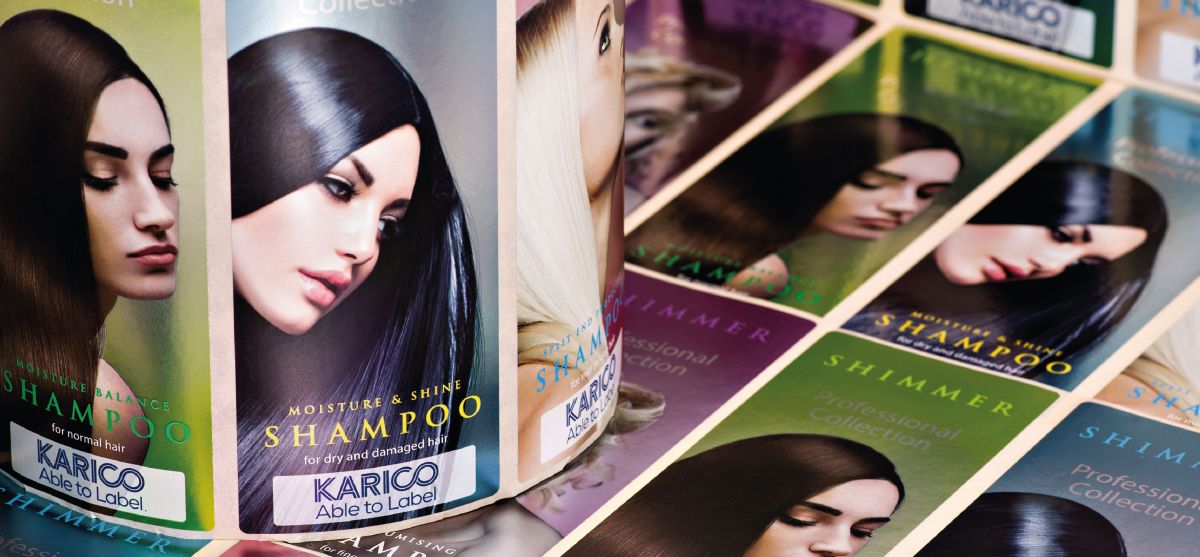

Karico is a printing house based in Espoo, and it specialises in the production of labels and stickers. It has recently invested in a 7-colour Domino N610i digital label press as part of a new roll-to-roll production line. Integrated with stations for flexo, foiling, varnishing, laminating, die-cutting and finishing, this modular digital hybrid installation is the first of its kind in Finland. The company plans to use this flexible and extended label production capability to gain new business in a variety of market sectors.

Established in 1976, Karico has been supplying a range of self-adhesive labels to customers in a wide variety of industries including the electro-technical, cosmetics, detergents and chemicals, trade and logistics, packaging, food and beverage, and the public sector. Providing barcode, product, brand and packaging, rating plate, warning, shipping and security labels, Karico’s active involvement in these areas generated a €1.8 million turnover in 2015.

Karico has been a pioneer in adopting UV ink jet technology for digital label printing, being one of the first companies to install a digital label press in Finland. Kimmo Palkonen, Managing Director of Karico, says, “We were already familiar with the technology having purchased our first UV ink jet system in 2009 and our customers have been praising its intense, vibrant colours ever since. UV cured inks are durable and extremely chemical resistant making them ideal for printing labels used on electrical equipment, detergents and chemicals.”

Digital printing offers benefits for both small businesses and high volume label producers. No printing plates are required which means savings in tool costs, money, and operator time for setup and job change. This makes it ideal for versioning, language and seasonal variations, and for marketing promotions.

Palkonen continues, “With shorter runs, the benefits of digital are quite obvious. However, we were looking for a solution that could truly compete with flexo presses for longer runs. After visiting Labelexpo Americas in 2014 and researching the market, we made a shortlist of three digital press manufacturers, whom we then visited. We were impressed with the Domino’s drop size, the white ink opacity and the extensive colour gamut.”

Domino Karico DigitalHe continues: “At Labelexpo Europe in 2015, we made the decision to invest in the 7 colour Domino N610i digital label press. This new technology delivers even higher print quality and improved colour reproduction than we previously had, along with increased operating speed and print width, and easy setup. I’d say quality and speed were the two determining factors behind our decision.”

Domino Karico DigitalHe continues: “At Labelexpo Europe in 2015, we made the decision to invest in the 7 colour Domino N610i digital label press. This new technology delivers even higher print quality and improved colour reproduction than we previously had, along with increased operating speed and print width, and easy setup. I’d say quality and speed were the two determining factors behind our decision.”

Ruud Bos, Business Manager at Domino Digital Printing Solutions, adds: “While the benefits of a digital press are obvious with shorter runs, the N610i also challenges traditional flexo presses when the print runs are longer and the job structure is right. It is a versatile system perfectly equipped to answer the needs of a company such as Karico.”

Karico is also keen to highlight the benefits of Domino’s white ink. “The white ink in the colour set is highly opaque, making the print quality very attractive on clear and metallic substrates,” says Palkonen. “You can also print three dimensional, textured effects with the white ink giving the labels more depth and vitality. In addition, our hybrid system makes it possible for the labels to be varnished or finished with gold or silver foil. These added-value design capabilities enable brand owners to create distinctive, high impact labels that ensure maximum shelf appeal and we expect these to be of interest to a wide range of industries ranging from cosmetics to beverages.”

Palkonen concludes, “We are excited about our new, versatile, digital hybrid system which means that we can offer an ‘end-to-end’ labelling solution which can be reconfigured to suit the changing needs of our customers. Flexibility is a key part of our service approach - hence our company slogan ‘Able to Label’. Karico is celebrating our 40th anniversary in 2016 and we are convinced that this investment makes digital printing technology even more competitive and will enable us to gain new business, especially in the export markets.”