Agi & Sam use the digital advantage to create unique fashion fabrics 3 Agi & Sam use the digital advantage to create unique fashion fabrics 3 |

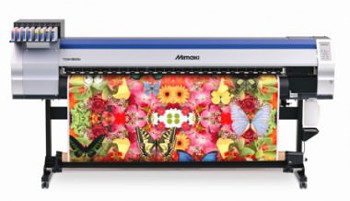

Agi & Sam's award winning Spring Sumer 2011 range featured designs printed on a Mimaki Tx400 digital printer._ Agi & Sam's award winning Spring Sumer 2011 range featured designs printed on a Mimaki Tx400 digital printer._ |

Meeting a rising star of the UK fashion industry was bound to be inspiring and as Sam Cotton from the very much on-the-radar Agi & Sam label enjoyed a day out from London at his print supplier; Macclesfield based R A Smart, Hybrid Services Ltd, (exclusive UK and Ireland distributors for Mimaki), tagged along to see what was round the corner for the exciting, young, menswear brand.

When Sam Cotton and Agape Mdumulla founded the UK’s well-known fashion label Agi & Sam in January 2010, they focused on integrating bespoke print with a sense of humour. It’s easy to forget that Cotton only graduated from the University of Lincoln’s illustration course in 2008 given the pair’s association with designers such as Karl Lagerfeld, Alexander McQueen and Armand Basi – among others. Cotton met Mdumulla, a Manchester College of Art graduate from the same year, while they were at Alexander McQueen. They are now moving their brand upwards at an impressive pace, and pioneering some standout work along the way.

Paris 2012

The purpose of Cotton's visit to Macclesfield is to discuss fabric sourcing with senior partner at R A Smart; Magnus Mighall. His company is a well-known print provider for fashion, furnishings and sportswear. It consistently has a number of household-name designs running through its substantial digital or high-end silk screen print facility. Since it was Paris Fashion Week when they met up, the spring / summer 2012 collection was uppermost in their minds today. Although digital print has brought deadlines much closer to delivery dates, there remained much work to get through.

‘Finding the right fabric remains a challenge,’ said Mighall, ‘although there are fewer obstacles now, as we can digitally print to almost any material with either dye sublimation, reactive, acid or pigment inks.’

Cotton agreed, remarking on the frustrations he faced: ‘The hardest thing has been sourcing interesting fabrics.’ The one he was keenest on tying down was a sweatshirt jersey with a looped, fleecy back to it. ‘It’s the most popular product in our range, and to find one that’s printable will be a real winner’, he said.

They’ll produce this next collection on the same digital printer that brought the plaudits and awards at London Fashion Week earlier in 2011. Their spring / summer 2011 collection entitled ‘Tabasco, Tequila and Tomato Juice’ was inspired by many facets of Central American society and delivered menswear, shoes and millinery that sported vibrant colour blocks and traditional cuts embellished with powerful printed patterns. The Mimaki Tx400-1800D textile inkjet printer that R A Smart used can print both direct and via transfer paper to the polyesters that make up most of Agi & Sam’s range. It long ago lost its reputation for being unfashionable and unpleasant to wear, polyester is by far the most versatile and creative base fabric available, morphing into substantially different handles, looks and weights with remarkable ease.

Great potential

From among the new fabrics for the upcoming collection, alongside some natty looking sportswear styled cloths, Cotton chose peached twill, ideal for a suit jacket’s outer fabric. With all the benefits to both manufacturer and consumer of ease of printing, wear and care, it has great potential to fit into Agi and Sam’s new range and one that Cotton was clearly excited about.

‘Dye sublimation is such an integral part of fashion printing and for next season we’re looking to mix natural cloths with man made fabrics in a contemporary and clean collection.’

One thing that surprised him was the lack of capacity for digital print provision onto polyester in the UK. ‘The majority of polyester is being printed for soft signage, sportswear or the flag industry,’ agrees Mighall, ‘and whilst there are a number of well-known bureau services for printing natural fabrics, I’m not surprised that Agi & Sam initially struggled to find a print partner for its polyester work.’

Hard graft

Agi & Sam produced its first commercial work not much more than a year ago, describing it at the time as ‘a fully committed menswear collection’. The company has embarked on the usual hard graft to gain the necessary uplift in a famously tough industry, and Cotton admits they are effectively building an expensive portfolio. They’re now at the stage where well-known labels request freelance projects. So together, he and Mdumulla are consulting for the big names and gaining the exposure that will elevate their brand.

‘With fashion, you have to make a scene,’ says Cotton. ‘Everything we do is tarnished with humour. We’re making print-based catwalk collections and getting noticed for it, but show by show, we’re pulling it back to a more normal perspective – we just had to create a fuss to get noticed at the outset.’

Sowing the seeds

The sample fabrics that R A Smart will produce for Agi & Sam to create its next runway pieces will be short work for the Mimaki, barely a few hours printing. But it’s sowing the seeds for the volume work that comes off the back of a successful collection launch. The beauty of digital lies in the ease of delivery of the short runs required for just such a project. Not long ago, it would have been a very different story for designers like Mdumulla and Cotton to get their work off the ground.

Cotton is completely accepting of this and sees digital textile printing – and his knowledge of it – as core to what their label offers. ‘A lot of people don’t really know much about the choice of processes, or how versatile digital printing is. What we’re keen on harnessing is where we can take it.’

The success of the Mimaki printed first collection was recognised by leading publications like Vogue, ID and Dazed. This has created something of a spike in demand at R A Smart, with a number of designers considering similar projects shortly after Agi & Sam’s showing at London.

Even so, Cotton’s not one for counting his chickens. ‘We had this plan. We hit all our targets. We delivered what we’d hoped for. But you know what? We could have done all this and had everyone hate it!’, he said.

The fickleness of fashion! But with a drive towards delivering its captivating designs on new ecologically savvy cloths, recycled polyesters and other challenging fabrics, Agi & Sam is happy working on the new, while others have yet to embark on the present.

Copyright © 2011, DPNLIVE – All Rights Reserved

One of Delta Group's HP Scitex FB500HP has just announced that Delta Display, part of the Delta Group, of London, has installed two additional HP Scitex FB7500 Industrial Presses and has also been beta testing the HP Scitex FB7500 Industrial Press Upgrade Kit.

One of Delta Group's HP Scitex FB500HP has just announced that Delta Display, part of the Delta Group, of London, has installed two additional HP Scitex FB7500 Industrial Presses and has also been beta testing the HP Scitex FB7500 Industrial Press Upgrade Kit.

The company is a leading provider of full promotional services for leading brands, retailer and entertainment companies providing print, distribution, logistical, and installation and compliance services.

Delta Display’s HP Scitex FB7500 Industrial Presses are at three locations: four at its Black Horse Road headquarters; one at its premises in Leeds, and two in a new plant in Waltham Cross.

Martin Shipp, Executive Director, Delta Group said:

"Campaigns for our customers can run up to 250 pieces and can be anything from multi-sheet graphics, canvas banners, self-adhesive vinyl graphics, corrugated POP displays, to leaflet and tabletop items. The FB7500 press gives us the flexibility we need to respond quickly since it can handle thin papers and plastics as well as thicker substrates for POP/POS displays."

The HP Scitex FB7500 Industrial Presses are capable of handling a wide variety of substrates ranging in thickness up to 25 mm at speeds up to 95 sheets per hour, with a production mode for indoor and close viewing applications of 48 sheets per hour.

The beta testing of the upgraded HP Scitex FB7500 Industrial Press is taking place at Black Horse Road and so far has enabled the company to see the benefits offered by the recently launched HP Scitex FB7600 Industrial Press. HP said that new features include a POP55 mode for 15% greater throughput; improved thin substrate handling; a multi-sheet feed capability to print four sheets simultaneously; edge-to-edge printing to reduce substrate waste and save finishing time, and a new HP FB225 Scitex Ink that offers increased flexibility and reduced chipping.

"The accuracy and speed of the multi-sheet option is impressive and double-sided printing can be done much more quickly and easily," Shipp said. "It shows great forward thinking in the development. By offering complete, integrated services, we have made it possible for our customers to have one supplier they can rely on which saves them time and, ultimately, money.”

Mark Rowland, HP Scitex County Manager, UK and Ireland added:

"The Delta Group is an important customer for HP," said Rowland. "The repeat orders of the FB7500 industrial presses, as well as the presence of multiple units of other HP Scitex, HP Designjet and HP Indigo presses and printers at Delta Group's production plants are indicative of the strong strategic relationship we have with the company and we are pleased to see its continued strong growth."

Follow HP on www.twitter.com/hpgraphicarts

Copyright © 2011, DPNLIVE – All Rights Reserved

Mimaki CJV30-60Mimaki’s exclusive UK & Irish distributor, Hybrid Services Ltd, will attend the Trophex 2012 exhibition at the NEC in January 2012, where it will demonstrate a range of digital personalisation printing solutions for the trophy, branded goods and promotional product markets.

Mimaki CJV30-60Mimaki’s exclusive UK & Irish distributor, Hybrid Services Ltd, will attend the Trophex 2012 exhibition at the NEC in January 2012, where it will demonstrate a range of digital personalisation printing solutions for the trophy, branded goods and promotional product markets.

The Mimaki CJV30-60 outdoor durable inkjet printer will be on show, featuring white and metallic ink suitable for creating decals, key fobs, trophy inserts, industrial labels, signs, graphics and more. Supplied with Mimaki’s RasterLink Pro RIP and FineCut cutting software, Hybrid maintains that at 610 mm in width it’s a ‘business in a box’ solution ideal for small office spaces and shops.

Alongside the roll-fed machine, Hybrid is also showing its flatbed UJF-3042FX. Trophex will actually host the UK debut for this new machine, which uses low energy LED UV cured ink to print to a multitude of products, making it perfect for imprinting phone covers, flame polished acrylic (for photo blocks), metal items, glass, plastics and more besides.

Mimaki UJF-3042FXWith an A3 printbed and a 50 mm head gap, incorporating a combination of vibrant process colours, white ink, clear varnish and a revolutionary printable primer, the UJF-3042FX offers production capabilities for companies constrained by the creative, run-length and setup issues of screen and pad printing.

Mimaki UJF-3042FXWith an A3 printbed and a 50 mm head gap, incorporating a combination of vibrant process colours, white ink, clear varnish and a revolutionary printable primer, the UJF-3042FX offers production capabilities for companies constrained by the creative, run-length and setup issues of screen and pad printing.

Hybrid is sharing its stand space with authorised reseller, Lineker Machines, who as well as Mimaki printers and cutters, can supply embroidery and heat transfer solutions. Mimaki hardware will also be available to view on The Magic Touch’s stand where the Mimaki CJV30-100 will be demonstrating its garment marking credentials.

Welcoming the opportunity of exhibiting at Trophex, Hybrid’s national sales manager, John de la Roche commented:

“Having a presence at Trophex is important for Hybrid as it allows us to meet with an important group of our customers and demonstrate Mimaki’s latest technologies,” he said. “The current Mimaki product line-up includes a number of standout technologies ideal for this market, so it’s a great opportunity for all concerned.”

Further information on Mimaki’s complete product range can be found at

Copyright © 2011, DPNLIVE – All Rights Reserved

Mimaki TS34 1800AMimaki has just announced that it is set to launch a new 1.8 metre wide, production dye sublimation printer early in 2012, the TS34-1800A. The new printer has been designed specifically for the sublimation printing market with Mimaki making high speed production and high end quality a key to its success. Sublimation transfer printing is widely utilised for sportswear applications due to the elasticity and quick-drying capability of polyester material as well as in the growing market of soft signage applications, such as flags, retail point of sale and exhibition graphics.

Mimaki TS34 1800AMimaki has just announced that it is set to launch a new 1.8 metre wide, production dye sublimation printer early in 2012, the TS34-1800A. The new printer has been designed specifically for the sublimation printing market with Mimaki making high speed production and high end quality a key to its success. Sublimation transfer printing is widely utilised for sportswear applications due to the elasticity and quick-drying capability of polyester material as well as in the growing market of soft signage applications, such as flags, retail point of sale and exhibition graphics.

The new printer has a staggered array of two newly developed print heads which give the Mimaki TS34-1800A the ability to run at printing speeds up to 32 m2/hr at 540 x 720 dpi. In addition, the machine can also achieve a printing speed of 17.7 m2/hr in six colour mode at the same resolution, where superior quality prints, with smooth gradations of tone and colour are required.Mimaki maintains that these features will make the TS34-1800A suitable for both large-sized soft signs and apparel applications, two key elements which respectively require a quick response and fine image quality.

Mimaki TS34-1800A is an ideal solution for producing sportswearIn addition to this increased print speed and quality, a number of additional functions have been incorporated to deliver improved productivity of the machine by enabling automated continuous operation. Mimaki’s UISS function enables the setting of two ink cartridges per colour in four colour mode. The result is that when an ink cartridge is depleted, the system switches automatically to the second cartridge of the same colour, preventing the printing process from stopping.

Mimaki TS34-1800A is an ideal solution for producing sportswearIn addition to this increased print speed and quality, a number of additional functions have been incorporated to deliver improved productivity of the machine by enabling automated continuous operation. Mimaki’s UISS function enables the setting of two ink cartridges per colour in four colour mode. The result is that when an ink cartridge is depleted, the system switches automatically to the second cartridge of the same colour, preventing the printing process from stopping.

An optional Mimaki Bulk Ink System (MBIS) provides large volume continuous ink supply with two litre ink sacks to ensure that overall ink costs along with users’ environmental footprint are substantially reduced. Mimaki is also offering an optional drying fan which increases the ink drying speed significantly, enabling continuous media take-up even during high speed printing.

Commenting on the launch of the machine, Duncan Jefferies, Marketing Manager for Hybrid Services ltd, Mimaki’s exclusive UK and Ireland distributor said, “The new Mimaki TS34-1800A delivers a competitively priced solution at a popular width and with powerful production capabilities. The response from our specialist textile resellers suggests they’re already confident the dye sublimation market will very quickly adopt this machine for volume output. Using aqueous ink to print to polyester ensures this new Mimaki printing solution has excellent green credentials as well.”

The TS34-1800A, packaged with Mimaki’s RasterLink Pro- RIP software, will be available from early 2012 through Hybrid’s authorised reseller network.

Tel: 0044 (0) 1270 501900

Image Group Flagmesh Image Group Flagmesh |

Image Group Flagmesh Image Group Flagmesh |

When Madhouse Associates, a leading UK integrated marketing communications agency, recently moved to new headquarters in the heart of Manchester they called in FBI (Flexible Business Interiors) and The Image Group UK to transform its new offices into a modern and exciting place to work.

Concept

FBI asked Image Group to provide, amongst other things, some fabric banners. This time however the brief was - with a twist! Image Group decided to print a collage of images from Madhouse’s portfolio, direct to flagmesh using its Mimaki Tx400-1800D. This high end production, wide format textile printer features Mimaki’s latest Sb210 disperse inks, recently upgraded by technicians from Mimaki’s exclusive UK & Irish distributor, Hybrid Services.

Because of an increasing demand for printed fabric graphics, The Image Group has invested significantly in state-of-the-art printers and dye sublimation processes in order to offer a rapid turnaround on fabric graphics for exhibitions and displays, point of sale applications and retail environments. Its creatively driven team has produced flying banners, feather flags, even custom tablecloths and marquees.

Image Group’s Dan Fleming commented, "The new ink upgrade really helped us to get the best out of our Mimaki,” he said. “It delivers superb sharp detail and vivid colours direct to flagmesh. Without these stunning pieces of print, the concept behind the twisted graphic would have been wasted."

The Image Group

Hybrid Services Ltd

BA Tail BA Tail |

BA Terminal BA Terminal |

British Airways (BA) has announced that it intends to further reduce its digital printing, scanning and mailing costs by using Xerox UK to manage its mailroom and reprographics operations.

As part of a five-year Enterprise Print Services contract, Xerox’s job will be to simplify BA’s mail-handling operation. They will manage the delivery of thousands of pieces of internal and external mail and speed up the production of critical in-flight printed materials. The Managed Print Services strategy is part of a wider British Airways document management plan to improve process efficiency.

Mark McCarthy, Procurement Executive at British Airways said:

“British Airways has a culture of consistently improving customer service, and we expect our providers to support us in keeping this level of commitment. Xerox is more than a supplier – they have been a trusted partner for 16 years and with them focused on printing and streamlining our document processes, we can use our energy and time to focus on bringing British Airways customers the best service in the sky.”

Due to the vast quantity of more than one million items processed through British Airways’ mail-handling operation at London Heathrow and London Gatwick airports, Xerox has partnered with MITIE Business Services to create a mail and distribution services hub in Uxbridge – about six miles from Heathrow Airport. However due to BA’s high security standards, specially trained staff at the dedicated facility will carry out full security screening of all inbound mail items and associated courier deliveries.

Amanda Abernethy, Director and General Manager of Global Document Outsourcing for Xerox UK added:

“British Airways needed to find a partner that could tackle complex back-office functions. With our expertise in document management, we have simplified and improved British Airways’ mail-handling operation. The next phase of the project involves the migration of the airline’s mail processing to a digital platform that feeds directly into its internal workflow, introducing further efficiencies.”

Originally signed in 1995, Xerox will continue to retain its existing agreement with BA, which involves the delivery of printed materials such as technical publications, in-flight services and training manuals, as well as payroll printing. These operations, which produce around 26 million documents per year, will also run from the Uxbridge facility.

statistics from the annual research of marketers and consumers on the health of the direct mail industry in the uk

statistics from the annual research of marketers and consumers on the health of the direct mail industry in the uk

Annual research of marketers and consumers on the health of the Direct Mail industry in the UK, carried out on behalf of TNT Post UK by fast.MAP and a survey by TNT Post UK to their customers, has found that DM appears to indicate a strong performance in the next twelve months, despite the current economic situation in Britain. The positive outlook reflects a resurgence of spending on DM particularly by financial services and FMCG companies. Of those respondents who took part in the survey 76% said they expect DM volumes to remain stable or grow in the next twelve months.

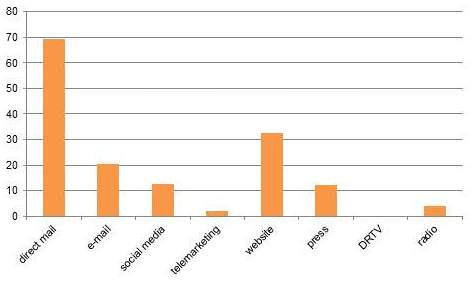

All this is of course is good news for the digital print industry particularly those companies involved in variable data print. Another interesting statistic to emerge from the survey was that 69%of respondents believe that DM is their most important promotional medium, followed by a website at 33%and email at 20.4%.

These facts seem to fly in the face of all the online marketering which has developed over the last year or so and begs the question of whether the web has become too invasive, or has DM just learned a lesson in how to communicate better, more targeted and less intrusive!

Commenting on the results Lieneke Happel, Director of Marketing and Strategy, TNT Post UK said: “We are pleased that direct mail continues to be seen as the most effective promotional tool used by marketers and that it is holding its own in a very competitive landscape. The consumer insights were revealing and present some creative opportunities for DM users knowing that many of their targets will read DM in bed or even on the loo!”

Interestingly it seems that consumer habits relating to DM vary. The majority of recipients prefer to read their DM as soon as they pick it up from the door mat and for those who wait till later in the day most read it on the couch in the living room (65%), followed by at the kitchen table (52%), in the garden (23 %) and 18 % on the toilet. There is also an age and gender difference in where people look at their DM. Males are far more likely to read direct mail either in the toilet or at work than females and the young are most likely to read it in bed and in the toilet.

Tells you something about our reading habits maybe!

About TNT Post

TNT Post is the second largest UK postal company and has the resources to deliver both addressed and unaddressed items. It currently handles more than 200 million items a month.

New Mimaki JFX200-2531 to offer larger printing area and improved productivity

![]() New Mimaki JFX200-2531 offers increased bed size and productivty

New Mimaki JFX200-2531 offers increased bed size and productivty

Mimaki has announced a forthcoming addition to its popular and much-lauded JFX200 product family. The JFX200-2531 LED UV flatbed printer builds on the success of the JFX200-2513 model with a significantly increased printing area and greatly enhanced productivity.

Company teams up with acclaimed photographer to launch ‘Carefully Curated’ initiative.

This showcases Don’s photography in a larger format than ever previously published. This portrait of a steel worker in India is printed across a double page in volume 3, Landscapes, Travel & Still Lifes

This showcases Don’s photography in a larger format than ever previously published. This portrait of a steel worker in India is printed across a double page in volume 3, Landscapes, Travel & Still Lifes

As a result of being invited by one of the 20th Century’s greatest British photographers, Don McCullin, to help him realise a three-volume Limited Edition retrospective of his life’s work – Irreconcilable Truths, Antalis UK has launched ‘Carefully Curated’ as a result of this venture. The aim of the initiative is to highlight the importance of selecting the right paper to produce high-quality, high-profile printed output.