Company says new range is a key addition to its

signage and graphical display portfolio.

Audi

Audi

UK based Antalis (formerly known as Antalis-McNaughton) has announced that it is now stocking the Orafol range of plotter vinyl’s, digital vinyl and laminates, along with sheets and reels for screen and UV offset printing.

It is one of the leading distributors of communication support materials in the UK and Ireland, with a portfolio range of over 13,000 products which includes papers, envelopes and consumables, as well as packaging, promotional and visual communication products. Antalis has 16 logistic centres across both countries.

The company said that the range of Oracal plotter vinyl’s are suitable for indoor and outdoor applications, vehicle wrap, glass cover and illuminated installations in a wide selection of colours.

It added that for customers who require digital vinyl’s and laminates, it was now also stocking the full range of Orajet vinyl’s including soft PVC, special PVC, polymeric and cast material with Oraguard laminates to match.

Screen and litho customers are also being catered for and can purchase the range of Oracal removable and permanent vinyl’s, including the popular 1640 and 1620 100mic sheets and reels, through to the high tack and polyester films required in the market.

Mick Crook, Product Manager for Antalis commented: “The Orafol products are key additions to our existing portfolio of strong brands which are targeted at the signage and graphical display markets. Orafol’s name and reputation has been built on consistently manufacturing premium quality products which meet the demands of a market that requires high performance, innovation and cost efficiency.” Crook continued: “We have already seen a lot of interest from our customer base and have had to increase our stock volumes and range to accommodate the demand.”

The product is also available in Northern Ireland and The Republic of Ireland.

For further information please contact Samantha Brown, Communications Manager at Antalis on 0044 (0) 1530 505153.

Follow us on Twitter - @DigiPrintNews

Like us on Facebook www.facebook.com/dpnlive - click the ‘LIKED’ button/top of page as well

Copyright © 2013, DPNLIVE – All Rights Reserved

Innovative solutions on show at

Packaging Innovations 2013.

A package designed with an angular auto-locking base enabling it to pack flat for easy storage and to fold out into a rigid “A” shaped box for retailLeo Luxe, a leading global supplier of packaging design, printing and manufacturing has announced that it will showcase its new luxury packaging concepts at Packaging Innovations 2013 (NEC, Birmingham, 27-28 February 2013, Stand C39). The companies theme for the event is ‘Put your best look forward', and items on display will include a wide-ranging portfolio of foldable rigid setup boxes, rigid boxes, luxury paper bags and further developments with sound applications.

A package designed with an angular auto-locking base enabling it to pack flat for easy storage and to fold out into a rigid “A” shaped box for retailLeo Luxe, a leading global supplier of packaging design, printing and manufacturing has announced that it will showcase its new luxury packaging concepts at Packaging Innovations 2013 (NEC, Birmingham, 27-28 February 2013, Stand C39). The companies theme for the event is ‘Put your best look forward', and items on display will include a wide-ranging portfolio of foldable rigid setup boxes, rigid boxes, luxury paper bags and further developments with sound applications.

Leo Luxe is in the business of providing added-value, end-to-end service for luxury product categories such as premium drinks and cosmetics. Its packaging designs are enhanced by a constantly expanding range of finishes and secondary processes such as graining, flocking, embossing and frosting that add various textures and patterns. The company recently added the Color-Logic Process Metallic Color SystemTM which now also offers Leo Luxe customers a new range of decorative effects using metallic substrates, metallic inks and clear films. All of these techniques are designed to be mixed and matched to create numerous product diversifications, with the purpose of giving customers an added edge in the market.

It will also be demonstrating new applications including OpticVision technology, which creates a dramatic dimensional effect using layered imagery to achieve a 3D appearance, to differentiate packaging at point of sale. In addition, other samples will incorporate sound, using ultra-thin switching technology to introduce pre-recorded sound bites when certain areas are touched. Leo Luxe explained that the sound modules are customised to the product, enabling an interactive packaging experience and unique selling proposition.

Another exhibition highlight will be the expansion of the foldable rigid setup box collection, encapsulating square, rectangular, angular and triangular shapes in various sizes.

"This assortment of unique constructions differentiates products at point-of-sale and simultaneously reduces shipping costs with no extra manufacturing implications," explains Cuan O'Callaghan, Leo Luxe. "Auto-locking bases and lids enable the packaging to open flat for easy storage and then fold up into a rigid box for retail."

The Leo Luxe ‘Visioneering Guide' will also feature on the stand. This is an approach Leo Luxe implements that creates a more integrated connection between the designer, brand and customer to deliver an effective design strategy. Visitors will be able to see how the process combines package structure, materials, graphics, special surface effects and interactive technologies into unified packaging solutions that it believes deliver a unique brand look and compelling message at retail.

Cuan O'Callaghan added: "We are delighted to be exhibiting at Packaging Innovations again this year and are looking forward to showing visitors our continuous developments in innovative package design. Our team is dedicated to researching the latest trends and technologies to offer cutting-edge packaging and provide a complete supply chain service to bring products to market."

http://www.leoluxepackaging.com/

Follow us on Twitter - @DigiPrintNews

Like us on Facebook at www.facebook.com/dpnlive

Copyright © 2013, DPNLIVE – All Rights Reserved

A fresh approach to display graphics

with revolutionary alternative.

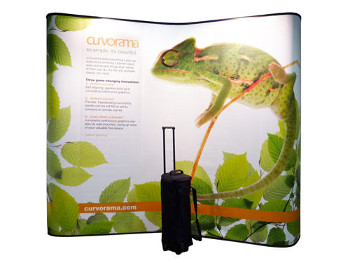

Curvorama offers flowing curves and ease of use Originally known throughout the display graphics industry for its Picture Wall product, UK based Fresco has turned the popup display on its head with the recent introduction of a revolutionary alternative – Curvorama.

Curvorama offers flowing curves and ease of use Originally known throughout the display graphics industry for its Picture Wall product, UK based Fresco has turned the popup display on its head with the recent introduction of a revolutionary alternative – Curvorama.

Since the early 1990s, managing director Miles Harris has sought to create a modular display system that offered a vast expanse of image, with no intrusive frames. “A seamless picture was always my goal” he says, “and we’ve always tried to design products for customers that ‘do more’”.

The Curvorama concept makes use of material manufacturer, Soyang’s anti-curl SoFlat pull up banner media coupled to flexible header and base units with magnetic ends. This allows what looks on the face of it to be a standard roller banner display, to morph into a multi-drop, curvy and gapless graphics backdrop. With reusable graphics elements, the system benefits print companies, end users and of course, the environment. “Recycling is good,” says Harris, “but reusing is far, far better.”

Fresco strives to make products that deliver more than just the sum of the parts to its customers. “We create products that are useful, reusable and ‘repurposeable’ – products where we get to work long term with our clients,” explained Harris.

The Curvorama product evolved from evaluating traditional popup displays and seeing how to make them better. With a carriage weight and packed size a fraction of that of a usual popup, it’s easier to manoeuvre and can even be shipped as hand baggage on some aircraft. So innovative is the product that it currently has three patents, but it was a long haul for the company to get the mating of popup and roller banner right.

“We tried many ways to join multiple drops – low tack adhesives, electrostatics, Velcro and others, but they just didn’t do the job. However, we firmly believe that if you can get customers to bring you problems, we can turn them into products,” added Harris.

A key element to the system’s success is its utilisation of the Soyang SoFlat material that Fresco prints on its Mimaki JV33, thus ensuring perfect registration and panel matching tolerance.

Fresco’s Miles Harris and the company’s Mimaki JV33 Fresco’s Miles Harris and the company’s Mimaki JV33 |  The portability of Curvorama can be a real benefit when transporting displays The portability of Curvorama can be a real benefit when transporting displays |

Fresco is not just about its Curvorama product – but its innovative thread runs through the business with products such as a highly successful educational role play Street Feet road safety training kit, developed in conjunction with Road Safety GB and endorsed by road safety charity, Brake. Making full use of the company’s broad range of print capability and instilling the concept of ‘learning by doing’, the well thought out kits feature non-slip solvent printed heavyweight textile roads and pavements, vibrant dye sub printed hi-vis tabards and felt/rubber waffle floor prints to denote destinations for the school children to travel between. These feature alongside rigid signage & street furniture and it’s all packed in a very neat carry case.

Sold into primary schools, the product has received numerous plaudits and recommendations from users and organisations and delivers a valuable revenue stream for Fresco, alongside its traditional digitally printed range of products for the indoor, outdoor, exhibition, display and signage markets.

Fresco will be demonstrating its Curvorama product alongside other industry suppliers at the inaugural Wide Format Wave event, to be held at Mimaki distributor, Hybrid Services Ltd’s showroom in early February 2013. To book a place on this, free, skills learning event, visit www.wideformatwave.co.uk.

Further details on the Curvorama product can be found by visiting www.curvorama.com, the Street Feet and other interactive kits from the Fresco range are showcased at www.frescointeractives.co.uk and their main site is www.fresco.co.uk.

Follow us on Twitter - @DigiPrintNews

Like us on Facebook at www.facebook.com/dpnlive

Ultra-high resolution digital printer with photonic printing technology.

digital print logoFaversham House, the organisers of Digital Print UK have announced further details of the show including one exhibitor promising a UK first for the inaugural cross-industry event at the National Exhibition Centre in Birmingham from the 5th-7th of November 2013.

digital print logoFaversham House, the organisers of Digital Print UK have announced further details of the show including one exhibitor promising a UK first for the inaugural cross-industry event at the National Exhibition Centre in Birmingham from the 5th-7th of November 2013.

LumeJet says that Digital Print UK will be the ‘perfect opportunity’ to showcase its new printer and future business developments. The company based in Coventry has developed LumeJet® photonics technology for the digital printing, patterning, exposing and marking of photo (light) activated media.

This will be the first public appearance in the UK for the new LumeJet S200 billed as an ultra-high resolution printer with “revolutionary photonic printing technology”. LumeJet maintains that for the first time it makes it possible to combine true photographic images with legible text and line art to create compelling output for marketing literature, photobooks and book jackets.

Miles Bentley, Commercial Director for LumeJet, said: “We chose Digital Print UK because it aligns well with our own aims, ambitions and progression as an organisation. By November, LumeJet printers will have been in the market for almost nine months, moving from beta sites to full production systems. Digital Print UK is the perfect opportunity to present a business case for the ultra high quality output achievable with LumeJet S200 printer. It’s also an ideal showcase for the future developments we already have in the pipeline.”

Rudi Blackett, Digital Print UK Show Director, added: “We’re delighted that LumeJet sees our show as the perfect opportunity to showcase its new printer and other business developments. I am sure that other companies will be planning more significant announcements at Digital Print UK, which will bring together senior-level delegates at the UK’s leading exhibition venue over three days.

“We’re seeing a growing confidence in the UK marketplace and continual demand for UK-specific print shows. The feedback we are getting is that exhibitors, both large and small, are now looking to niche events such as Digital Print UK as a key target market for sales opportunities and networking. We already have bookings from a cross-section of the supply chain.”

http://www.digitalprintuk.net/

The LumeJet S200 print mechanism The LumeJet S200 print mechanism |  The LumeJet S200 twin digital print head (DPH) configuration The LumeJet S200 twin digital print head (DPH) configuration |

Online store investment made to streamline and improve print services across campus.

Loughborough University web-to-print solution Digital StoreFrontUK based Loughborough University has been able to streamline its design and print services and work towards improved control of its corporate identity across all types of printed applications due to the implementation of EFI's web-to-print solution Digital StoreFront . The introduction of a more refined workflow has resulted in reduced departmental costs, simplified online ordering and execution of jobs, resulting in increased throughput and efficiencies across all production equipment.

Loughborough University web-to-print solution Digital StoreFrontUK based Loughborough University has been able to streamline its design and print services and work towards improved control of its corporate identity across all types of printed applications due to the implementation of EFI's web-to-print solution Digital StoreFront . The introduction of a more refined workflow has resulted in reduced departmental costs, simplified online ordering and execution of jobs, resulting in increased throughput and efficiencies across all production equipment.

Loughborough is one of the UK’s leading universities, with an international reputation for research that matters, the quality of its teaching, strong links with industry, and a high achievement in sport and academic disciplines. For the past 30 years its design and print services have played a key role in the success of the university by providing departments, and on- and off-campus organisations with professional design, print, photography, video and web design services.

"We were aware that having an online store, and managing it in-house, would enable us to streamline and improve our print services across campus,” stated Helen Clarke, Business and Administration Manager. “It provides an accessible workflow for users, so after consultation with other universities and councils we chose EFI’s Digital StoreFront. We have seen a dramatic take up of the service throughout October 2012, providing an 82 per cent increase in job submissions since the software was installed. Because it is essential that a coherent and consistent visual identity is applied across all of our communications, we will be moving forward with Digital StoreFront to provide a simplified collection of document templates that our print customers can use both on and off campus, and that support our documented visual identity guidelines."

Powered by EFI Fiery® front-ends, which provide a direct link to Digital StoreFront, Loughborough University's print facilities focus on a Canon imagePress 1135 production engine with inline finishing and a Canon imagePress C7000 for colour production, with complementary wide-format printers, booklet makers, folding, binding and stitching equipment. EFI pointed out that the ability to offer such a broad range of services from a large number of sources relies on a sleek and efficient interface with users. This said the company highlights the value of Digital StoreFront in educational environments as well as within the commercial print sector.

Company continues migration of POS/POP

and other graphic displays from screen to digital.

Tim Boore, head of digital technologies, Image FactoryHP has announced that Image Factory, of Chippenham, Wiltshire, UK, has installed an HP Scitex FB7600 Industrial Press. The purpose of the investment is to offer cost-effective, versatile solutions for customers and allow the company to continue the migration of POS/POP and other graphic displays from screen to digital.

Tim Boore, head of digital technologies, Image FactoryHP has announced that Image Factory, of Chippenham, Wiltshire, UK, has installed an HP Scitex FB7600 Industrial Press. The purpose of the investment is to offer cost-effective, versatile solutions for customers and allow the company to continue the migration of POS/POP and other graphic displays from screen to digital.

This latest installation follows the installation of an HP Scitex FB7500 Industrial Press less than a year ago.

In October 2011, when HP launched the FB7600 press, it also made an optional Upgrade Kit available to HP Scitex FB7500 Industrial Press users. Image Factory has added the optional HP Scitex FB7500/FB7600 White Ink Kit to one of its presses and can use HP FB225 White Scitex Ink on the full range of substrates.

"The addition of the white ink was part of the process to phase out screen printing," said Tim Boore, head of digital technologies, Image Factory. "The results are excellent and it is far more cost-effective. The ability to print white really puts the last nail in the coffin for screen as far as we're concerned. We will retain our last screen line for one- and two-colour jobs and special projects requiring metallic inks, but our normal work is going to be digital."

For Image Factory, the migration from screen to digital is a reflection of the change that is occurring in the marketplace. It’s about being able to deliver what to-days customers want, at a price they want to pay and making a decent return.

"The speed and capacity of these printers has enabled us to shut down one of our three screen printing lines, and when we've completed the options and upgrades, we'll be able to shut down a second,” continued Boore.

The HP Scitex FB7600 Industrial Press uses UV-curable inks and is capable of imaging a broad range of substrates, from films, papers, and boards to more unusual materials like metal, glass and wood up to 25mm thick. With the optional multi-sheet loader on both presses enabling the simultaneous printing of four sheets, Image Factory believes it is able to maximise productivity.

"The result of these investments is that we have presses with identical functionality that enable us to move work from screen to digital," Boore explained.

While the market remains challenging, Boore feels that Image Factory is well positioned to give its customers the quality and service that they want, while ensuring its competitiveness and margins.

"Using our MIS system we have been monitoring our press speeds, ink, and material use and production throughput carefully," he said. "The presses are performing at the levels promised by HP, and our customers have been impressed with the improvements in the print quality and speed of delivery."

The HP Scitex FB7600 Digital Press can print up to 95 full-size sheets per hour, but for POP/POS display quality, POP55 mode (up to 55 sheets per hour) offers maximum productivity of 290 m2/hr.

More information is available at www.youtube.com/hpgraphicarts

http://www.imagefactoryuk.com/

Copyright © 2012, DPNLIVE – All Rights Reserved

New HP Indigo 5600 digital press completes ambitious investment programme

Steve Bottoms and Donna Roche (Head of Graphics and Digital Print) with the new HP Indigo 5600 Digital PressUK based Plastic Data Card Ltd, of Chatham, Kent, has installed an HP Indigo 5600 Digital Press with One Shot Colour capabilities, Thick Substrate Kit and white ink option. The new investment is for the production of high-quality, plastic cards for its blue-chip customers.

Steve Bottoms and Donna Roche (Head of Graphics and Digital Print) with the new HP Indigo 5600 Digital PressUK based Plastic Data Card Ltd, of Chatham, Kent, has installed an HP Indigo 5600 Digital Press with One Shot Colour capabilities, Thick Substrate Kit and white ink option. The new investment is for the production of high-quality, plastic cards for its blue-chip customers.

Throughout 2012, the company has been updating its production facilities and modernising its premises on the back of a growing demand for higher quality and more distinctive cards. It added an automatic cutter for the production of cards in different shapes, and a new foiling machine was also installed to produce distinctive, added-value cards. The final part of the investment programme was the installation of an HP Indigo 5600 Digital Press.

“Our business had expanded and we wanted to increase production capacity and develop new products and services,” said James O’Carroll, managing director, Plastic Data Card Ltd. “The new press has a range of features that we believe will take the business forward, enabling us to add new services and commercial products, like itinerary lists, flyers and leaflets, as well as a wider range of cards."

The HP Indigo 5600 Digital Press can print 34 A3 sheets per minute in full colour or 40 in Enhanced Productivity Mode. This is equivalent to more than 40,000 standard, rectangular plastic cards per hour – double the speed of the company’s previous press.

The use of plastic cards continues to increase with more and more new applications coming into use every year. Plastic Data Card produces more than 10 million cards annually and the new HP Indigo digital press is designed to enable the company to print on more than 2500 different substrates, including coated and uncoated papers, synthetics, dark, transparent, metallic and recycled media.

With the One Shot Colour option, all colour separations are accumulated on the offset blanket and transferred to the substrate simultaneously in a single pass. This provides registration and enables the printing of synthetic materials including PVC, PET, Teslin® and PC. The Thick Substrate Kit means that stocks up to 18pt (460 microns) can be printed, expanding the range of cards that Plastic Data Card can offer its customers. The ability to print HP Indigo ElectroInk White further extends the variety of choice by enabling it to print on clear or coloured substrates.

“One of our key markets is providing cards for concerts and music festivals,” O’Carroll explained. “Cards for backstage or VIP passes require high-quality branding and often include barcodes and signature strips – and can be up to A5 in size.”

The HP Indigo 5600 Digital Press is Plastic Data Card’s third Indigo digital press. It replaces the company’s Indigo Omnius Card Press, installed in the late 1990s.

More information about HP is available at www.youtube.com/hpgraphicarts

http://www.plasticdatacard.co.uk/

Copyright © 2012, DPNLIVE – All Rights Reserved

Company cites increased productivity and new ink enhancements as major benefits.

The 3 founders of 1st Byte, Tony Anderson (left), Lawrence Dalton and Stuart Williams (right) with the new HP Indigo 7600 Digital Press1st Byte Print, a London-based digital print service provider, has installed an HP Indigo 7600 Digital Press. The purpose of the investment was to increase its production capability and to meet its customer demands for a more varied and differentiated product mix.

The 3 founders of 1st Byte, Tony Anderson (left), Lawrence Dalton and Stuart Williams (right) with the new HP Indigo 7600 Digital Press1st Byte Print, a London-based digital print service provider, has installed an HP Indigo 7600 Digital Press. The purpose of the investment was to increase its production capability and to meet its customer demands for a more varied and differentiated product mix.

1st Byte specialises in short-run, fast-turnaround high-quality printed products and installed its first digital press, an Indigo e-Print 1000+, when it was established in 1997.

The company has upgraded its presses several times, and the new 7600 Digital Press replaces one of its three HP Indigo press 5000s.

"The increased productivity of the 7600 digital press means the net result is like having an extra machine," said Lawrence Dalton, managing director, 1st Byte Print. "The new on-press enhancements are already proving popular with our customers who can enjoy special effects without having to wait the extra time for them to be created in separate processes. Sometimes the work would need to be sent out, adding even more time."

HP said that the Indigo 7600 Digital Press offers print speeds of up to 120 full-colour A4 pages per minute (ppm) and up to 160 full-colour ppm in Enhanced Productivity Mode. It pointed to new on-press, on-demand special effects which can offer product differentiation and high-value applications.

Since the press was installed, 1st Byte has already generated a large variety of creative samples and jobs using these new special effects. One of these is HP Indigo ElectroInk Transparent which can be used in varying numbers of layers to create digital watermarks, spot UV varnish effects, and create raised print and textures for a highly distinctive, embossed look and feel.

"Our creative services department has produced samples using the press's ability to print on metallised substrates which have a powerful impact," added Dalton. "We've even created a sample that replicates the appearance and texture of full-grain leather."

1st Byte's Creative Services offer bespoke projects including the design, production and fabrication of a variety of books, including custom boxes, covers and dust-jackets. Books are printed on the HP Indigo presses. Covers, dust-jackets and box-wraps larger than HP Indigo press formats are printed on one of 1st Byte's HP Designjet Z6200 series printers.

"We have a wide range of finishing equipment, including hot foiling, gluing and case-book binding, as well as the more basic processes," Dalton explained. "With the flexibility of digital printing and our ability to deliver creative finishing options, customers have a very wide choice of solutions under one roof."

Situated in the heart of London's traditional print centre, 1st Byte predominantly serves business-to-business corporate clients, agencies, print management suppliers and other organisations that want the short-run, fast-turnaround, high-quality products that the company's HP Indigo presses and 24/6 production schedules can deliver.

"We're optimistic about the future," concluded Dalton. "We've continued to grow, adding 10 employees this year, as well as the additional capacity of the HP Indigo 7600 press."

More information is available at www.youtube.com/hpgraphicarts

Copyright © 2012, DPNLIVE – All Rights Reserved

Initiative designed to give customers the chance

to explore new applications

HP is running a free sample roll programme on selected substratesHP has announced that, in conjunction with its authorised UK reseller channel, it has decided to run a free sample roll promotion on selected media. The company said the aim was to encourage users of the HP Designjet Latex Printer to try HP's latest media.

HP is running a free sample roll programme on selected substratesHP has announced that, in conjunction with its authorised UK reseller channel, it has decided to run a free sample roll promotion on selected media. The company said the aim was to encourage users of the HP Designjet Latex Printer to try HP's latest media.

“This initiative gives our customers the chance to explore new applications made possible by different types of HP media, such as wallpaper, soft-signage or window graphics,” said Phil Oakley, UK & Ireland country manager, Designjet & Commercial Sign & Display, HP. “Our resellers can advise customers on the best media to test for the applications they may want to add to their portfolio.”

Existing HP Latex Technology users can contact their HP authorised reseller and request the desired media, although it will be limited to one roll of media per type and a maximum of five rolls in a three-month period. Full-width sample rolls of 10m in length will be available while supplies last.

Sample media currently available includes:

CR687A-S HDPE Reinforced Banner - 36in

CG419A-S Photo-Realistic Poster Paper - 36in

CG423A-S Permanent Gloss Adhesive Vinyl - 42in

CR661A-S Backlit Polyester Film - 42in

CG435A-S Heavy Textile Banner - 38in

CG445A-S Dupont Tyvek Banner - 42in

CG453A-S Permanent Matte Adhesive Vinyl - 42in

CH004A-S One-view Perforated Adhesive Window Vinyl - 42in

CH006A-S Light Textile Display Banner - 42in

CH010A-S White Satin Poster Paper - 42in

Q8838AE-S Satin Canvas - 36in

CG935A-S Air Release Adhesive Gloss Cast Vinyl - 54in

CH098A-S PVC-free Wallpaper - 42in

CR691A-S Double-sided HDPE Reinforced Banner - 36in

CH037A-S Clear Gloss Cast Over Laminate - 54in

More information about HP is available at www.youtube.com/hpgraphicarts

Copyright © 2012, DPNLIVE – All Rights Reserved